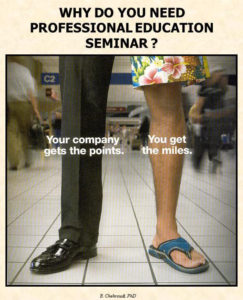

Seminars are prepared for and delivered to professional design engineers, practitioners, R&D technical managers, and researchers. Seminars are from three to five days in a row and involve both presentations and group discussion sessions. Seminars come with up-to-date, targeted, tailored slides and hand-picked articles. The presentation style is to enhance understanding and build physical intuition on key issues and provide design guidelines based on experience. In many cases, the seminars were followed by, or packaged with, consulting opportunities on pressing R&D needs of key players in a variety of industries. Many of our consulting services are originated through such seminars. For this and similar professional activities, Dr. Chehroudi was honored with the Forest R. McFarland Award in recognition of the outstanding services and leadership in contributions to Continuing Professional Development, Society of Automotive Engineers (2002).

For partial list of Seminars or combined Seminars/Consulting conducted click here: Seminars/Consulting conducted..

o Management, Leadership, and Strategic Planning in R&D Organizations, (https://www.asme.org/learning-development/find-course/effective-management-research-development-teams ) Management of Innovation, (Global Powertrain Congress, page 11). The seminar was initially offered at University of California at Los Angeles (UCLA) and subsequently adopted by ASME. (http://books.google.com/books/about/Effective_Management_of_R_D_Teams_and_Or.html?id=FcgcHAAACAAJ )

In today's technology-driven global economy, innovation is at the core of the survival-of-the-fittest organization. The innovation process begins with the identification of market needs or technology opportunity and then goes through stages, such as adopting or adapting existing technology that satisfies the identified need or opportunity, inventing when needed, and finally transferring this technology by commercialization or other instrumental means. Effective and efficient R&D management can have profound and determining consequences, considering the key role it plays in the economic health of a nation and the world as a whole, the profitability of a business enterprise, the effectiveness of a technology-based governmental agency, and the enormous investment nations make in R&D activities. Today, the complexity of the technology creates complex organizations in which many disciplines have to be coordinated. It is the manager's primary responsibility to bring components together so they can operate smoothly and harmoniously, each making an optimal contribution to the R&D organization.

Managing R&D organizations and concentrating on their productivity and excellence offers a unique set of problems and unusual challenges that are amplified when the team is scattered spatially in a global economy. This uniqueness arises primarily from two basic facts: (1) the character of the enterprise/technology, and (2) the highly-specialized, articulate, and autonomous people involved in R&D. As American economist and Nobel laureate Kenneth J. Arrow stated, "The central economic fact about the processes of invention and research is that they are devoted to the production of information." Obviously, the generation of information requires research and, in addition to the R&D organizations' focus on information, research involves considerable uncertainty because the outcome can never be predicted perfectly from the different inputs used. It will, therefore, become clear in this course that managing an R&D organization is largely the art of integrating the efforts of diverse, creative, intelligent, and independent individuals. The ideas presented in this course consist of the condensed works of a multitude of experts focusing on ways to improve the productivity of R&D and foster excellence and innovation in organizations.

The course is intended for all levels of managers, supervisors, and team/group leaders who wish to improve their leadership, management, motivational, and communication skills for creating optimum individual and team performance in R&D organizations as well as management of technology. It is particularly useful to scientists, engineers, project managers, and other technical personnel who intend to make a transition to management positions in an R&D environment or who want to improve their own leadership and/or followership skills. It also is beneficial for faculty members, group leaders, department heads, technology managers, research administrators, managers responsible for sponsoring research, and policy makers in science and technology.

Lecture notes and cases studies: 980 pages.

________________________________________

o Combustion and Emission for Engineers-Chemical and Physical Aspects, (https://www.sae.org/learn/content/97011/)”

A good understanding of the physical and mathematical principles of the combustion process will permit engineers to effectively contribute to emission control strategies and design and develop emission control systems and components. In addition, this seminar will build sufficient background to enhance interdisciplinary collaboration between research and development, design, and manufacturing engineers. Issues related to combustion and emissions will be brought "down to the earth" with minimal use of mathematical terms and maximum application of physical explanations and analogies. However, the notes for this seminar are intended to be "reasonably complete" so that an engineer who desires to go beyond the objectives of this seminar, may do so by merely reading the included notes. For this reason, some of the handouts relate to advanced mathematical formulas that are not essential and not covered in the seminar itself.

This seminar introduces the jargon of combustion and emphasizes the definitions and necessity for precise usage of these terms. Equilibrium species composition, its meaning, limitations, and applications are discussed. Chemical kinetics terms and concepts are explained and their utilization is demonstrated in the context of explosion and hydrogen/hydrocarbon (HC) fuels oxidations. Autoignition, flame structure and propagation, and flammability limits are discussed. Combustion, flame structure and speed, burning speed, turbulence and turbulent burning speed, cyclic variability of combustion, and partial burning and misfire are among the subjects covered in the context of combustion engines. Also discussed are the formation of major pollutants such as, nitric oxides, carbon monoxide, and unburned hydrocarbons. The formation of minor species are described in brief. Effects of engine design and operating parameters are also emphasized and discussed. Finally, after-treatment of pollutants in the exhaust system including catalytic conversions is described.

Design and lecture notes: 1005 pages.

________________________________________

o Liquid Atomization, Sprays, and Fuel Injection Systems/Technologies, (https://www.sae.org/learn/content/98019/).

Atomization of liquids is at the very heart of operations of many of the devises we use on a daily basis. From our shower in the morning (liquid water atomization process at the shower head), to liquid-fueled engines in ground transportation, to gas turbine in airplanes/power stations and rocket engines , we rely on the efficient and low-pollutant-level operation of these devices. This seminar is based on the realization and proven experience that knowledge of technological practices and advances in one discipline, say, diesel fuel injection, is highly beneficial to engineers in other areas of engineering and technology such as, for examples, gasoline direct injection (GDI) or rocket engines and vice versa.

This seminar is about understanding the processes of liquid atomization and spray formation and relating this understanding to fuel injection systems and emission of pollutants in modern engines. Fuel injection is the key to smooth, efficient, and low-emission operation of the gasoline-fueled engines. In diesel and GDI engines, it is shown that the story is also the same and even more critical. In the aerospace industry, the engine thrust, efficiency, and the emission levels are directly related to the performance of the liquid fuel injector designs. In short, the liquid fuel atomization and spray formation is in the heart of the majority of stationary and mobile power generation machines. Other areas such as electrostatic car-body spray painting, agricultural crop spraying, ink jet printing, pharmaceutical nebulizers, spray drying, and chemical liquid rockets, are just a few examples of the very wide applications of the liquid spray production technology.

The approach in this course is to build sufficient background through introduction of a consistent and widely-used terminology in sprays and atomization. Justifications, reasons, and purposes of the liquid atomization and spray formation are discussed along with presentation of different designs of atomizers and nozzles employed in various industries. Characterization methods of sprays are discussed after the definition and meaning of different averaged liquid droplet diameters are touched. Droplet size measurement devices are covered and examples are shown. Armed with these critical background information, the focus of the course is then heavily directed to the gasoline and diesel fuel injections, injector designs and their performance requirements for optimum engine operation with lowest possible emission of harmful pollutants.

Design and lecture notes: 650 pages

________________________________________

o Ignition Technologies and Their Impact on Engine Performance, Efficiency and Emission, (https://www.sae.org/learn/content/c0131/)

Combustion (or burning) is a fast self-sustaining chemical reaction that releases a large amount of heat. Burning candles, forest fires, log fires, the natural gas burning in home furnaces, and the burning of gasoline in internal combustion engines are all examples of common combustion processes. Many of critical technologies today employ combustion as the key element of their operation. The objective is to convert the stored chemical energy of the "fuels" into thermal energy. To achieve this, three things must normally be present: a fuel, an oxidizer, and an ignition source. Today, nearly 85% of the world's energy is produced through combustion and hence is vital to our way of life. Therefore, it poses great challenge to maintaining a healthy environment. Improved understanding and control of ignition and thereby combustion will assist us in dealing with the problems of pollutants formation, performance, and fuel economy. To this end, it is crucial for engine design engineers to be aware of basic knowledge and recent advances in combustion-initiation (ignition) issues to more intelligently evaluate and harness their potentials.

The thermodynamic and fluid mechanical states of the unburned charge near and at the time of the spark strongly affect the quality of the combustion and therefore the emission of the pollutants from the engine. The engine performance and drivability are also strongly affected by a weak ignition. The so-called cyclic variability, which affects and bounds the lean and knock limits of an engine design is to a great degree influenced by the ignition system. Equally important, the ignition system can and is being used to provide local in-cylinder information on air-fuel ratio, misfire, knock, and mass fraction burned in each individual cylinder. Hence, great potential exists for applications of this information to attain a more fuel efficient and environmentally compatible engine.

This seminar starts with a concise yet effective review of the combustion issues and terminology in engine to establish a uniform knowledge base. Then the focus is turned on the fundamental knowledge on charge ignition. Commonly-used ignition systems are described next followed by the explanation of four phases of the spark ignition. Effects of key ignition variables on performance and emission of pollutants are described in details. After the introduction of some alternative ignition methods, a comprehensive presentation on engine diagnostic and control opportunities through use of ignition system is given. The ignition of ultra lean mixtures is fully covered next. Throughout the seminar emphasis is put on effects of ignition system on engine performance, efficiency and emission of harmful pollutants. Engineers in other areas than automotive will find this seminar very informative and useful for their ignition problems.

Design and lecture notes: 590 pages.

________________________________________

o Gas Turbine Engines _ Controlling Pollutants, (https://www.asme.org/products/courses/gas-turbine-engines-controlling-pollutants)

Emission of pollutants from gas turbine engines, whether they are implemented for use in aircrafts, ground-based energy conversion, or for mechanical drive applications, is one of the grand challenges of our time. By most estimates, energy conversion through combustion of fuels in gas turbines will remain one of the most important technologies in foreseeable future. Hence, design strategies for many gas turbine components, specifically combustors and fuel nozzles, are heavily guided by approaches to reduce and/or control the amount of regulated pollutants exhausted into the atmosphere. While there are commonalities between the two class of engines (i.e., aircraft and ground-based), there are sufficient differences in their low-emission technologies that worth consideration of both in one coherent and contrasting presentation. Therefore, it is the main objective of this seminar to present a balanced coverage of both aircraft and ground-based gas turbine engines in which commonalities and differences are described and highlighted to guide current and future low-emission design strategies.

Also, the course takes the view that thorough understanding of the formation mechanisms for the regulated pollutants is critical for intelligent and efficient engineering design strategies as well as for effective current and future technology development efforts. For this reason, the presentation, after a broad coverage of the requirements imposed on combustors in terms of metrics, constraints, and system interactions for both engine types, delves into the current understanding of how these pollutants (i.e., carbonaceous particulate matter, CO, and NOx) are produced within the combustion chambers. This is especially important to those who are new in the field, desire to fill knowledge gap with recently-developed understanding, or wish to migrate/expand from other engines, such as reciprocating internal combustion engines, into gas turbine emissions.

In the last part of the seminar, the attendees experience the interplay between essential understanding of combustion and emission of pollutants covered earlier and its transformation into the design of the current and future combustors in the context of aircraft and ground-based engines. Here, topics such as premixed or partially-premixed combustors designs, staging in lean-premixed prevaporized (LPP) mixture and its consequences on designs of the combustor components, prevaporization issues, degree of mixture homogeneity, combustion efficiency, lean stability, autoignition, flashback, fuel nozzles, and lean direct injection (LDI) are covered. Operability issues (such as, part-load emissions, stability and lean blowout, ignition, thermal managements, pattern factor, combustor pressure losses, combustion oscillations, and alternative fuels) are also presented.

After a thorough summary of the fundamental processes common in such engines, this three-day courses concludes with a comprehensive treatment of the conventional, nonpremixed, and dry low-NOx (DLN) combustor design strategies for ground-based gas turbines. In essence, the last part of the presentation (both for aircraft and ground-based engines) covers case studies from manufacturers and technology developers, emphasizing the system-level and practical issues that must be addressed in developing different types of gas turbines that emit pollutants at acceptable levels.

________________________________________

o Combustion and Emissions in Aircraft Engines, (AIAA Professional Education Course), initially prepared through a contract with NASA Glenn Research Center.

Most of the man-made emissions are generated on the earth’s surface and emitted into the atmospheric boundary layer up to about one kilometer. A large fraction of these pollutants return to the surface through wet or dry deposition. However, some penetrate beyond into the free troposphere and further depending on their atmospheric residence time. Aircrafts are the only high altitude man-made source of emissions. The effect of NOx on ozone creation or depletion is highly altitude dependent. Subsonic airplanes cruise at altitudes of 8-13 km whereas supersonic ones cruise at higher altitudes of around 20 km. The NOx emissions from subsonic aircrafts are considered to produce ozone, which is a strong greenhouse gas. However, the concern over environmental impact of aircrafts is not just due to the point of release of the emissions but also the projected rapid growth of the aviation industry. The uniqueness of the aircraft engine emission comes from the following factors. First, air traffic growth exceeds ground traffic growth rate. Second, pollutants of air traffic are emitted at high altitudes where they have a greater influence than those at the ground level. Third, increasing engine operating conditions (higher combustion chamber pressure and combustor inlet temperature) of modern highly-efficient gas turbine engine designs tend to increase the quantity of NOx per unit of fuel consumed.

Aircraft engines are regulated on the amount of pollutants they produce. The International Civil Aviation Organization (ICAO) sets the standards. The species that are regulated are NOx, CO, unburned hydrocarbon, and smoke. The increasingly stringent emission regulations remain the major driving force for civil aircraft gas turbine combustion research. While the best annular combustor technology is able to meet current regulations, the double annular combustors (DAC) have demonstrated a substantial reduction in NOx production. These low pollutant engines (already in service) are the starting point for ultra low emission combustors. A solid understanding of the mechanism of pollutants formations in the combustion chamber along with thorough knowledge of fuel combustion and design issues in gas turbine combustors are the main objectives of this seminar.

This seminar starts with a concise yet effective review of the combustion issues and terminology in engines to establish a uniform knowledge base. This requires sufficient knowledge on fuels, in particular, unique requirements of aviation fuels, and air quality at different altitudes. Fundamentals of combustion thermodynamics are effectively discussed next. Concepts such as equilibrium, adiabatic temperature, and heating values are explained. Then the focus is turned on the combustion chemistry in which topics such as reaction rate, autoignition, and reaction mechanisms are discussed. Flame propagation, stabilization, and quenching are covered next followed by some basic knowledge on liquid fuel drop evaporation and burning issues. Stirred reactor concept and efficiencies (combustion, thermal, propulsion) are adequately discussed with some examples. Detailed discussion of combustion, pollutant formation mechanisms, liquid fuel atomization and their complex interactions are presented next. Ignition issues such as altitude relight are sufficiently covered. A simple design problem is presented to describe the methodology. Near-term and long-term trends in combustor designs and their rational are fully presented towards the end of the seminar.

Design and lecture notes: 550 pages.

________________________________________

o Gasoline Direct Injections (GDI), (https://www.sae.org/learn/content/c1009/)

The quest for an even more efficient, smarter, and environmentally-cleaner liquid-fueled spark ignition (SI) reciprocating engine than the current multi-port fuel injection (MPFI) SI engines is more alive and intense now than ever before. In this effort the GDI SI engines have an important and special place. Some background information is of value to facilitate the understanding of the operation and potentials of the GDI engines. The history of the fuel/air mixture preparation system in SI engines starts with the carburetor units positioned in the intake system just prior to the throttle valve which itself is connected to the driver accelerator foot-pedal for manual load (or engine output torque and power) changes in these engines. For many years this served the purpose until the race for the higher performance, more fuel efficient, and cleaner-burn engine intensified that led to the MPFI SI engine design. In this design, an electronically-controlled fuel injector is used per each cylinder for fuel metering and targeting of the sprays towards the intake valves. In MPFI engines the amount of fuel injected can be independently controlled from the air flow and the replacement of the carburetor unit by the port injectors itself caused a better breathing capability (or higher so-called volumetric efficiency) of the engine leading to higher output torque and power levels. Higher volumetric efficiency means that each cylinder of the engine can bring more mass of air thereby providing the potential and opportunity for more fuel introduction and hence higher chemical energy release per cycle delivering a higher engine torque. In contrast, diesel engines use direct liquid fuel injection into the cylinder and rely on autoignition of the fuel itself with no external ignition sources such as spark plug or any other means. The load in these engines are varied by changes in the amount of the fuel injected and there are no throttle valves in the intake system. Therefore, the pumping work, a negative work or energy needed to pump air in and burned gases out of the cylinders, are nearly zero for diesel engines whereas it changes from a maximum value, at idle throttle valve position, to a negligible amount under full load at wide open throttle (WOT) valve position in SI engines. Note that the net indicated output work of an engine is equal to the total work during the compression and expansion strokes minus the pumping work. Pumping work is also referred to as throttling work losses in the automotive literatures. The absence of the throttling work losses (as a result of the lack of the throttle valve) for the direct injection (DI) diesel engine is also one significant advantage of the GDI engine design. This provides an opportunity for improvement in specific fuel consumption (SFC) over the current MPFI engines. In a sense a GDI engine is like a DI diesel engine but with a suitably-positioned spark plug and a gasoline fuel, instead of the easily auto-igniting diesel fuel, in-cylinder injection system. In practice, some degree of throttle control is usually required for GDI engines, compromising the SFC improvement potential.

Design and lecture notes: 692 pages

________________________________________

o An Introduction to Nanotechnology: Science, Technology, and Commercialization. (debuted first at UC Irvine)

The US government goes as far as suggesting that in just another 10 to 15 years, nanotechnology will impact more than $1 trillion per year in products and services.

The idea of building and working with structures in the “nano”-scale world goes back to Nobel laureate Richard Feynman’s famous lecture on December 29th, 1959 at California Institute of Technology titled “There’s Plenty of Room at the Bottom.” He envisioned engineering materials one atom at a time, a “bottom-up” approach.

An entity with a micron in diameter is (1/1000) of a meter and a “nano” sized object is (1/1000) of a micron, a dimension difficult to imagine and feel. For example, a human hair is about 50 to 100 microns (μm) in diameter, a white blood cell is about 10 microns, and a DNA is in the order of 10 nanometers (nm). Building brick by brick using atoms required tools unavailable in 1959. One approach is to hope that once these building blocks are unloaded on a land, they automatically form a desired building through the magical self-assembly properties observed in molecular world.

One breakthrough enabling technology towards bottom-up approach was demonstrated by IBM researchers in 1982. Binning and Rohrer invented the scanning tunneling microscope (STM) and won the noble prize in 1986. The atomic force microscope (AFM) was shortly after invented by Binning and Rohrer as well. It is now widely accepted that scanning probe techniques, including AFM, constitute a key enabling tool for nanotechnology. Another key element in nanotechnology is chemical self-assembly, the self-organization of small molecular components to form complex functional structures. As the feature length scale reaches the 70 nm or less in lithography through implementation of tools such as F2 lasers, and the fact that biological scales are in the nano size ranges, the nanotechnology is seen to heavily interact/overlap with biotechnology and microelectronics.

James Canton, President of the Institute for Global Futures stated, "Never has such a comprehensive technology promised to change so much so fast... Inevitably, nanotechnology will give people more time, more value for less cost and provide for a higher quality of existence.” Also, based on a broad definition that considers most biotechnology the "wet side" of nanotechnology, Rice chemistry professor and Nobel Laureate Richard E. Smalley likes to say that "it holds the answer, to the extent there are answers, to most of our most pressing material needs in energy, health, communication, transportation, food, water, etc." Finally, The US government goes as far as suggesting that in just another 10 to 15 years, nanotechnology will impact more than $1 trillion per year in products and services.

This seminar attempts to instill a sense of understanding and appreciation for the significance of this revolutionary (nano-) technology of the 21st century, and elevate knowledge of the field for the technologists, managers, business people, entrepreneurs and the investment community. This is accomplished through dissemination of a balanced and high-fidelity information on scientific, existing and potential products, and business opportunities for the near-, intermediate- and long-term. This seminar aims to position the attendees to intelligently benefit from current and future nanotechnology products and other related opportunities in their technical and business activities.

Design and lecture notes: 552 pages.

________________________________________

o Combustion and Emission of Pollutants in Diesel Engines: In-Cylinder Processes

The combustion inside a diesel engine cylinder is very complex due to its heterogeneous nature, where liquid fuel breakup, evaporation, fuel-air and burned-unburned gas mixing, and combustion chemistry occur simultaneously. Consequently, there are many in-cylinder processes that individually or often in combination impact diesel engine combustion quality, emission of pollutants, engine performance, and fuel economy. Dynamics of liquid jet breakup, atomization quality of the liquid spray and its time evolution, vaporization, turbulence, mixing and chemical reactions are key amongst the processes that go hand-in-hand to bring the combustion process to completion and deliver optimum performance with best fuel efficiency. At the same time, formation and oxidation of particulates, hydrocarbon formation/oxidation mechanisms, and nitric oxides generations occur which contribute to the exhaust emission levels. Although aftertreatment of the pollutants in the exhaust is an important means to manage emission levels to the environment, innovative in-cylinder measures and optimization strategies based on better understanding of the combustion and other related factors in the cylinder can substantially decrease the cost burden and technological complexity of the aftertreatment hardware. Indeed, this important aspect of diesel engine operation, meaning in-cylinder processes, is the focus, the motivation, and the central theme of the seminar. Factors such as chamber design, fuel injection characteristics, injector design and the ensuing spray quality, autoignition process, flow/combustion chemistry interaction, and combustion diagnostic/control are amongst key variables to be understood and optimized.

On the other hand, emission standards for diesel engines are increasingly tighter due to severe health and environmental effects of particulates and other pollutants. For example, the Tier 2 US federal emissions standards for diesel car and trucks, especially the Bin 5 level, are considered the most stringent requirement for engine manufacturers. The most demanding standards are set for NOx (nitric oxides) and particulates in that order. Considering the need to meet increasingly stringent standards with no compromise in, but improvement demands on, efficiency/performance, it appears timely to discuss the nature of diesel engine in-cylinder processes for fuel economy improvements and understand the mechanism of formation and emission of three important pollutants, namely, NOx, particulates, and hydrocarbon.

Therefore, ample time is spent on understanding in-cylinder phenomena and their diagnostics/control strategies. To the extent that the inclusion of aftertreatment options affects the in-cylinder combustion/emission processes or vice versa, they are briefly presented.

Design and course notes: 950 pages.

________________________________________

o Liquid Atomization, Spray, and Fuel Injection in Aircraft Gas Turbine Engines (recently approved by the AIAA Propellant and Combustion Committee, https://www.aiaa.org/home/events-learning/courses-workshops/detail/liquid-atomization-spray-and-fuel-injection-in-aircraft-gas-turbine-engines )

Atomization of liquids is at the heart of operations of many of the devices we use on a daily basis. From our shower in the morning (water atomization at the shower head), to liquid-fueled engines in ground transportation (gasoline and diesel engines), to gas turbine in airplanes/power stations and rocket engines. Other areas such as electrostatic car-body spray painting, agricultural crop spraying, ink jet printing, pharmaceutical nebulizers, spray drying, and chemical liquid rockets, are just a few examples of the very wide applications of the liquid spray production technology.

In the aerospace industry, the engine thrust, efficiency, and the emission levels are directly related to the performance of the liquid fuel injector designs. For this reason, R&D activities in this area have intensified in the past two decades in a quest to design and operate efficient and low-emission gas turbine engines. It is imperative

This seminar is about understanding the processes of liquid atomization and spray formation and relating this understanding to fuel injection systems and emission of pollutants in modern engines. The approach in this course is to build sufficient background through introduction of a consistent and widely-used terminology in sprays and atomization. Justifications, reasons, and purposes of the liquid atomization and spray formation are discussed along with presentation of different designs of atomizers and nozzles employed in various industries. Characterization methods of sprays are discussed after the definition and meaning of different averaged liquid droplet diameters are touched. Droplet size measurement devices are covered and examples are shown. Armed with these critical background information, the focus of the course is then heavily directed to gas turbine fuel nozzle designs and their performance requirements for optimum engine operation with lowest possible emission of harmful pollutants.then individuals involved in research, design, and operation have the requisite knowledge and training to choose intelligent and innovative approaches when it comes to liquid fuel nozzle and its optimum performance.

Design and course notes: 600 pages

|