A Three-Day Seminar

(Tailored to the customer needs)

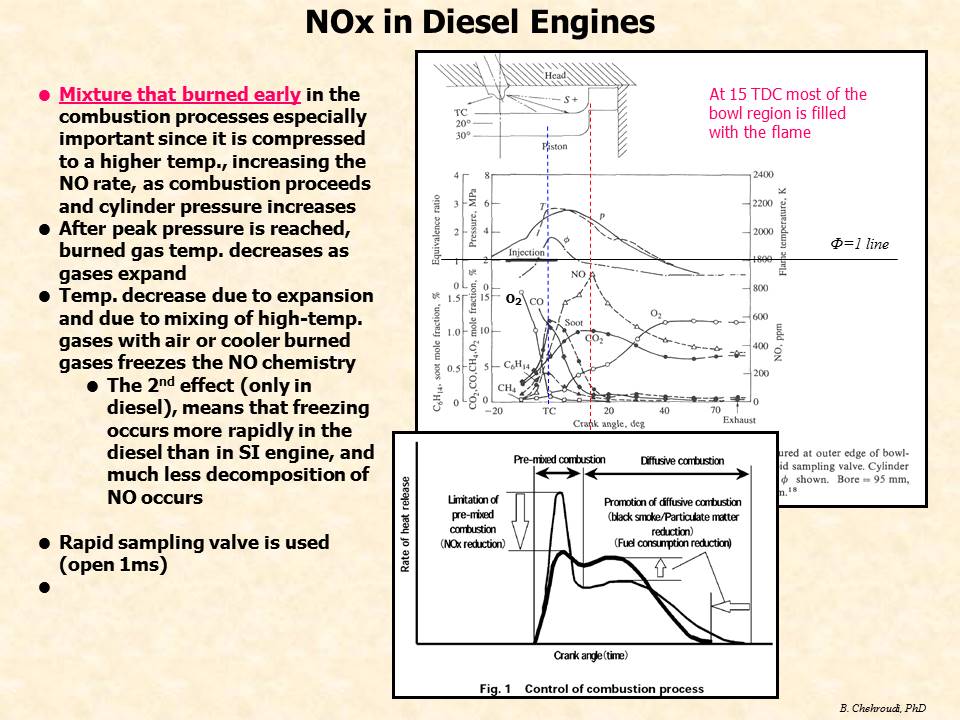

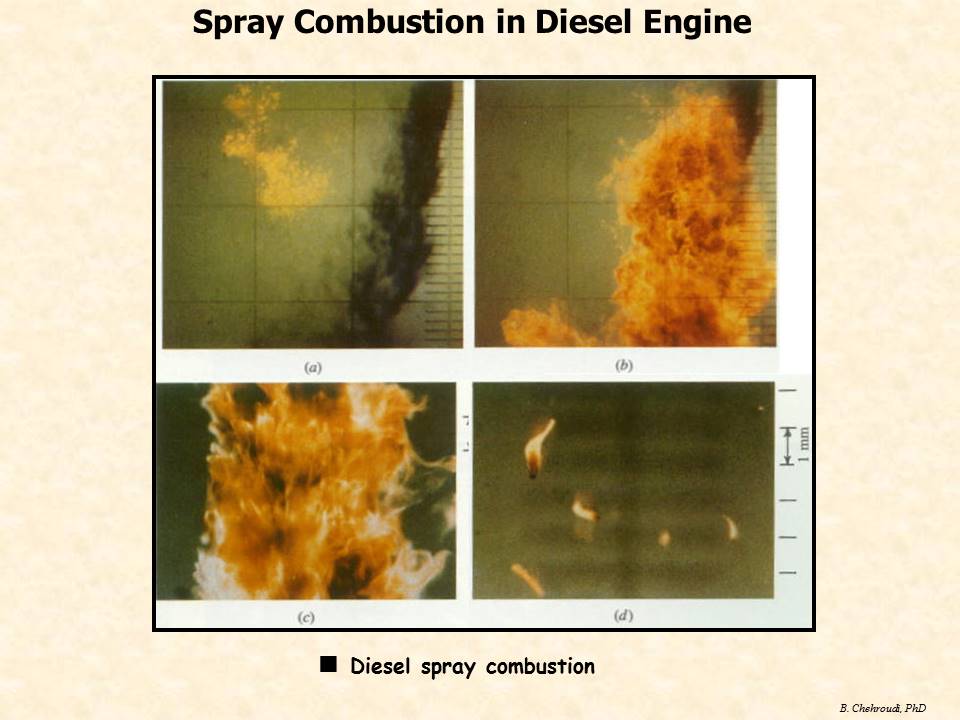

The combustion in diesel engines is very complex due to its heterogeneous nature, where liquid fuel breakup, evaporation, fuel-air and burned-unburned gas mixing, and combustion occur simultaneously. Consequently, there are many processes that could contribute to diesel engine combustion and emission of pollutants.  Dynamics of liquid jet breakup, vaporization, mixing and chemical reactions are key processes that go hand-in-hand in order to bring the combustionprocess to completion. At the same time, formation and oxidation of particulates, hydrocarbon formation/oxidation mechanisms, and nitric oxides generations occur which contribute to the exhaust emission levels. Although aftertreatment of the pollutants in the exhaust is an important measure to manage emission levels to the atmosphere, innovative in-cylinder combustion control strategies are always preferred. It is this philosophy that motivated major efforts on preparation of this short course for diesel engines and is the basis of most discussions here. Therefore, extensive time is spent on understanding in-cylinder phenomena and their control strategies. On the other hand, emission standards for diesel engines are increasingly tighter due to severe health and environmental effects of particulates and other pollutants. For example, the Tier 2 US federal emissions standards for diesel car and trucks, especially the Bin 5 level, are considered the most stringent requirement for engine manufacturers. The most demanding standards are set for NOx (nitric oxides) and particulates in that order. For example, the phase-in value (Bin 8) is 0.2 g/km, to be reduced to Bin 5, which requires 0.07 g/km averaged across an automaker’s light-vehicle fleet. This is 50% reduction from its previous standard. The Bin 5 level is set for the year 2007 with full implementation for all cars and light-duty trucks planned by year 2009. Considering the urgent need to meet the standards with no compromise in efficiency, it appears timely to discuss the nature of the combustion in diesel engines for fuel economy improvements and understand the mechanism of formation and emission of three important pollutants from diesel engines, namely, NOx, particulates, and hydrocarbon. To the extend that the inclusion of aftertreatment options affects the in-cylinder combustion processes or vice versa, they are presented in details.

Dynamics of liquid jet breakup, vaporization, mixing and chemical reactions are key processes that go hand-in-hand in order to bring the combustionprocess to completion. At the same time, formation and oxidation of particulates, hydrocarbon formation/oxidation mechanisms, and nitric oxides generations occur which contribute to the exhaust emission levels. Although aftertreatment of the pollutants in the exhaust is an important measure to manage emission levels to the atmosphere, innovative in-cylinder combustion control strategies are always preferred. It is this philosophy that motivated major efforts on preparation of this short course for diesel engines and is the basis of most discussions here. Therefore, extensive time is spent on understanding in-cylinder phenomena and their control strategies. On the other hand, emission standards for diesel engines are increasingly tighter due to severe health and environmental effects of particulates and other pollutants. For example, the Tier 2 US federal emissions standards for diesel car and trucks, especially the Bin 5 level, are considered the most stringent requirement for engine manufacturers. The most demanding standards are set for NOx (nitric oxides) and particulates in that order. For example, the phase-in value (Bin 8) is 0.2 g/km, to be reduced to Bin 5, which requires 0.07 g/km averaged across an automaker’s light-vehicle fleet. This is 50% reduction from its previous standard. The Bin 5 level is set for the year 2007 with full implementation for all cars and light-duty trucks planned by year 2009. Considering the urgent need to meet the standards with no compromise in efficiency, it appears timely to discuss the nature of the combustion in diesel engines for fuel economy improvements and understand the mechanism of formation and emission of three important pollutants from diesel engines, namely, NOx, particulates, and hydrocarbon. To the extend that the inclusion of aftertreatment options affects the in-cylinder combustion processes or vice versa, they are presented in details.

Benefits of Attending

Upon completion of this seminar, you will:

- Gain a comprehensive understanding of the important processes in combustion and emission

- Develop the background and necessary foundation to educate yourself beyond the depth and topics covered

- Learn the formation mechanisms and reduction strategies of pollutant species in combustion systems

- Understand the effects of engine design and operating conditions on combustion and emission

- Be able to communicate effectively with engineers working on combustion and emission aspects in your company

- Grasp the technology and the logic behind after-treatment of pollutants

- Discover the role chemical kinetics plays in the design of low-emission combustion systems

- Effectively contribute to the design of critical components such as combustion chambers and exhaust systems

- Identify design trade-offs between increasing engine performance and maintaining low emission characteristics.

Who Should Attend:

This seminar will be especially valuable for engineers, technical and project managers, researchers, and academicians. Presently, the design of many components in engines are affected by combustion and emission control measures to meet customer's, federal and local government's demands and regulations. Hence, engineers working on the design of components for high efficiency and performance of combustion engines as well as those directly and indirectly involved in reducing emission of harmful polluta

nts from combustion engines will highly benefit from this course. Additionally, this course provides adequate background for engineers and managers in contact with those directly involved in combustion and emission issues and will prepare them for more efficient and intelligent communication in an interdisciplinary environment. Environmental engineers desiring to expand their understanding of combustion and emissions from engines will benefit, as well as, engineers active in the development and application of software for the modeling of thermal-fluid, combustion and emission processes.

How to Arrange for a Presentation:

Due to ATC's low overhead, direct-contact clients are offered a competitive and cost-effective ATC. Individuals interested in these seminars should contact Advanced Technology Consultants (ATC) directly. Alternatively, this seminar (prepared by the ATC and delivered by a award-winning ATC consultant) are also sponsored by the Society of Automotive Engineers (www.SAE.org).

Electronic and hard copies of the seminar materials can be purchased and are only available through ATC. Contact ATC for price and shipping.

NOTE: Professionally-prepared "audio-video Powerpoint-type presentations" of these seminars are available for purchase by the companies. Each slide is presented with a clear audio by the consultant, describing the subject, while a digital pointer guides the audience to where the attention is to be focused. Companies can put such audio-video presentations on their intranet to be used by their employees. It is a cost effective way approaching professional training which also contributes towards R&D, design, and intelligent new product development. Presentations are updated every year at a fraction of the original cost. For more details and pricing contact ATC.

Seminar Content

DAY ONE

- Thermodynamics review

- First law

- Second law

- Reversibility I

- Diesel gas cycles

- Combustion in Diesel Engines

- Definitions

- Three phases of combustion

- Combustion chamber design considerations

- Models-properties of working fluids

- Heat release diagram

- Fuels and fuel quality

- Introduction – natural fuels and background

- Petroleum and its products

- Paraffins/alkenes

- Olefins/alkenes

- Aromatics

- Alcohols

- Vapor pressure

- Fuel For CI Engines – specifications

- Diesel fuel classifications

- Effect of sulfur

- Effect of aromatics

- Effect of other fuel properties

- DME

- Emulsions

- Fischer tropsch

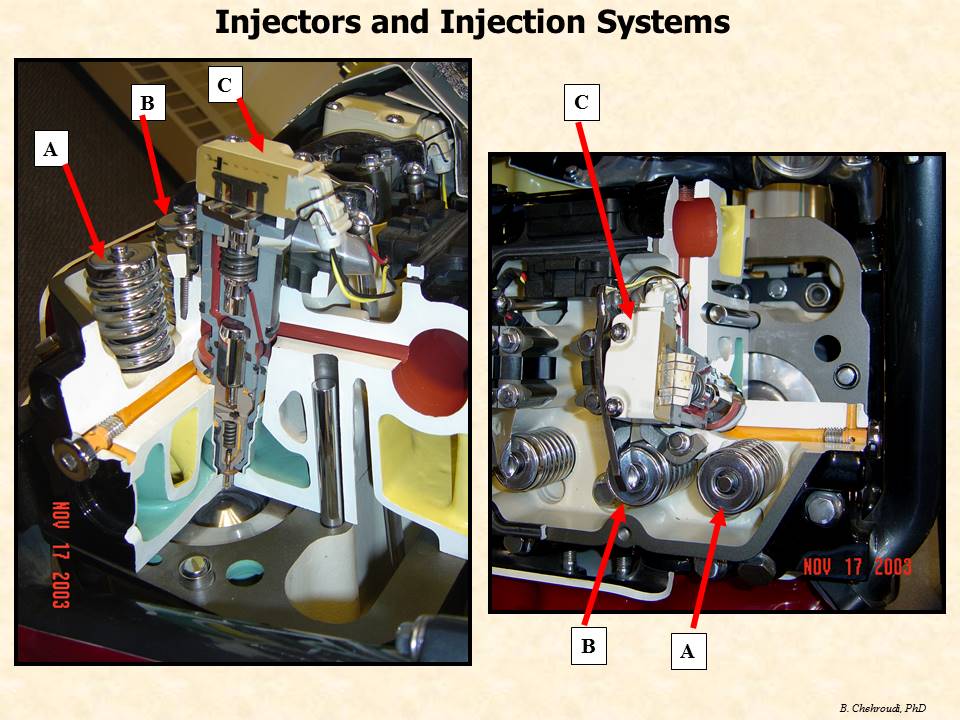

- Diesel fuel spray, injector and injection system

- Fuel injection system

- Pumps (concise coverage)

- In-line injection pump

- Distributor-type injection pump

- Single-barrel injection pumps

- Unit injector & unit pump

- Injector designs

- Nozzle holder

- Nozzles

- Others

- Overall spray structure

- Liquid fuel atomization

- Spray angle

- Intact core length

- Spray penetration

- Effects of several parameters on mean droplet diameter

- Spray evaporation

- Advanced topics (details of split injection, common-rail injection, interacting-sprays injection, ultra-high pressure fuel injection, and others effects on performance and emissions)

- Pumps (concise coverage)

- Fuel injection system

DAY TWO

- Diesel combustion & emissions in DI engines

-

- Diffusion combustion

- Factors affecting the combustion process

- Combustion influence on fuel economy

- Combustion influence on emissions

- Fuel quality

- Autoignition

- Ignition delay

- Effects of fuel injection parameters on ignition delay period

- Heat release rate and mixing-controlled combustion

- Effects of fuel injection on ignition delay and on engine performance, efficiency, and emissions

- HC emission mechanisms in diesel engines and its relation to fuel injection

- Soot formation and fuel sprays

-

- Effect of A/F on particulate/smoke

- Effect of charge air cooling on PM

- Turbocharger optimization for PM control

- Features of Modern Diesel Engines

- Regulatory constraints/design targets

- NOx control

- Fuel economy vs NOx control

- Effect of injection pressure

- Combined effect of injection timing and charge air cooling

DAY THREE

- Post-Combustion Emission Control Devices (Aftertreatment)

- Particulate matter analysis

- Oxidation catalysts

- 3-way catalytic converter

Selective catalytic reduction

Selective catalytic reduction- Particulate filters

- Combination trap/catalyst systems

- Lean NOx traps

- Lean NOx catalysts

- NOx aftertreatment

- Particulate aftertreatment

- Cold start issues

- Emerging engine technologies

- Motivators

- EGR systems

- Water injection/emulsion

- Special post-combustion emission control devices & systems

- Non-thermal plasma

- Non-thermal plasma assisted catalysts