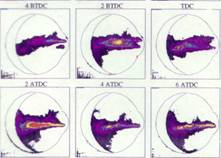

Left image: Oscillating poppet injector producing a hollow-cone spray.

Right image: Interacting-sprays injection system shown at different crankangles (or time). Note that sprays impinging the far cylinder wall

(picture is taken by sending a pulsed laser sheet and imaging from cylinder head using ICCD digital camera)

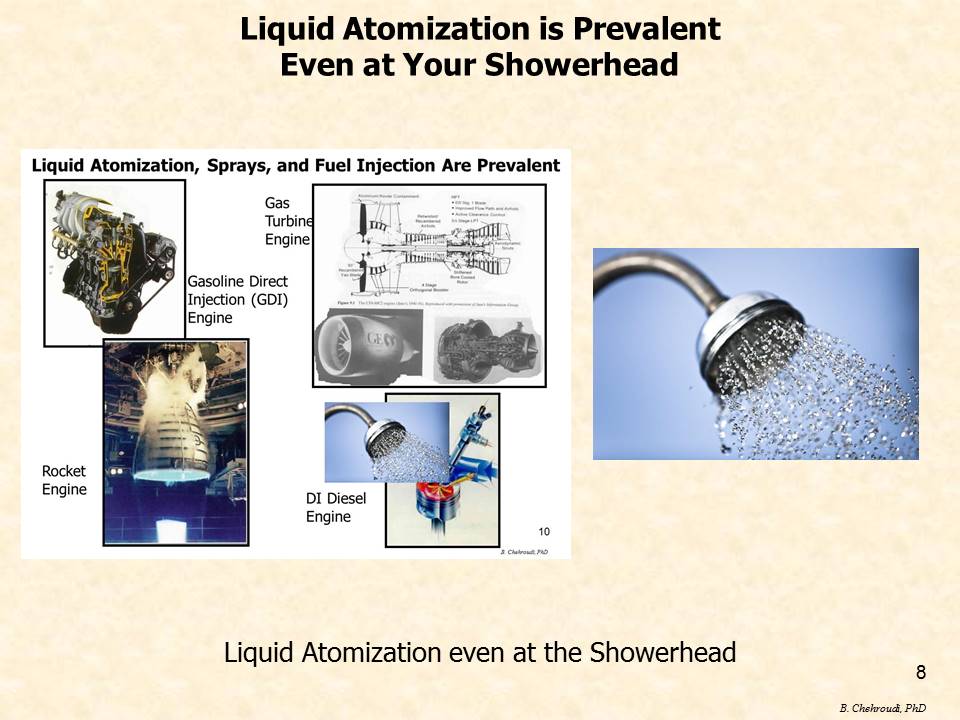

Atomization of liquids is at the very heart of operations of many of the devises we use on a daily basis. From our shower in the morning (liquid water atomization process at the shower head), toliquid-fueled engines in ground transportation, to gas turbine in airplanes/power stations and rocket engines , we rely on the efficient and low-pollutant-level operation of these devices. This seminar is based on the realization and proven experience that knowledge of technological practices and advances in one discipline, say, diesel fuel injection, is highly beneficial to engineers in other areas of engineering and technology such as, for examples, gasoline direct injection (GDI) or rocket engines and vice versa.

This seminar is about understanding the processes of liquid atomization and spray formation and relating this understanding to fuel injection systems and emission of pollutants in modern engines. Fuel injection is the key to smooth, efficient, and low-emission operation of the gasoline-fueled engines. In diesel and GDI engines, it is shown that the story is also the same and even more critical. In the aerospace industry, the engine thrust, efficiency, and the emission levels are directly related to the performance of the liquid fuel injector designs. In short, the liquid fuel atomization and spray formation is in the heart of the majority of stationary and mobile power generation machines. Other areas such as electrostatic car-body spray painting, agricultural crop spraying, ink jet printing, pharmaceutical nebulizers, spray drying, and chemical liquid rockets, are just a few examples of the very wide applications of the liquid spray production technology.

The approach in this course is to build sufficient background through introduction of a consistent and widely-used terminology in sprays and atomization. Justifications, reasons, and purposes of the liquid atomization and spray formation are discussed along with presentation of different designs of atomizers and nozzles employed in various industries. Characterization methods of sprays are discussed after the definition and meaning of different averaged liquid droplet diameters are touched. Droplet size measurement devices are covered and examples are shown. Armed with these critical background information, the focus of the course is then heavily directed to the gasoline and diesel fuel injections, injector designs and their performance requirements for optimum engine operation with lowest possible emission of harmful pollutants.

Benefits of Attending:

Upon completion of this seminar, you will:

- Understand and be familiarized with important terminology commonly used in atomization and sprays

- Gain a general physical understanding of the important processes in atomization and spray formation

- Possess adequate background and foundation to educate yourself beyond the depth and topics covered

- Be able to intelligently judge, adapt, and, transfer technological advances from one discipline to the other

- Understand effects of injection system design and operating conditions on engine performance, combustion and emission of pollutants

- Be able to communicate intelligently with engineers working on injector and injection system design aspects in your company

- Grasp the technology and the logic behind different injector designs

- Gain sufficient knowledge to intelligently contribute to human being's efforts in minimizing emission of pollutants and maximizing efficient usage of earth's energy resources

- Anticipate future trends and technology developments in fuel injection

- Learn and appreciate the role the injection system plays in combustion and emission and how it is used to provide guidance in design of low-emission combustion systems

- Effectively contribute to the design of the critical components such as intake valve and induction system

Who Should Attend:

This seminar will be especially valuable for engineers, technical and project managers, researchers, and academicians in the automotive and aerospace industries. In the automotive industry, engineers working on the design of components for high efficiency and performance of combustion engines, particularly those directly and indirectly involved in reducing emission of harmful pollutants from combustion engines, will highly benefit from this course. Additionally, this course provides adequate background for engineers and managers in contact with those directly involved in the fuel injection systems. Therefore, this course experience prepares the attendees for a more efficient and intelligent communication in an interdisciplinary technological environment. Furthermore, aerospace engineers involved in the design of the gas turbine or rocket engines' combustion chambers will find the course useful and enlightening. The course is also of interest to academicians wishing exposure to the field and those engineers active in development and applications of software, modeling in-cylinder injection combustion and emission processes.

How to Arrange for a Presentation:

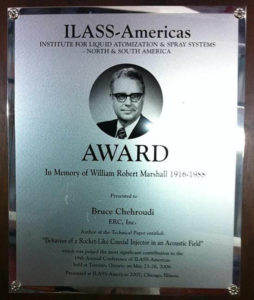

Due to ATC's low overhead, direct-contact clients are offered a competitive and cost-effective package. Individuals interested in these seminars should contact Advanced Technology Consultants (ATC) directly. Alternatively, this seminar (prepared by the ATC and delivered by a award-winning ATC consultant) are also sponsored by the Society of Automotive Engineers (www.SAE.org). Click on Atomization&FuelInjection to see this seminar on SAE page.

Electronic and hard copies of the seminar materials can be purchased and are only available through ATC. Contact ATC for price and shipping.

NOTE: Professionally-prepared "audio-video Powerpoint-type presentations" of these seminars are available for purchase by companies. Each slide is presented with a clear audio by the consultant, describing the subject, while a digital pointer guides the audience to where the attention is to be focused. Companies can put such audio-video presentations on their intranet to be used by their employees. It is a cost effective way of approaching professional training which also contributes towards R&D, design, and intelligent new product development efforts. Presentations are updated every year at a fraction of the original cost. For a sample presentation click on the word "SPRAYS" in the picture to get a feel of how information is transferred (High-speed internet access is recommended. Otherwise, download may take a few more minutes). For more details and pricing please contact ATC.

Seminar Content

Day 1

- Description of the Atomization Process

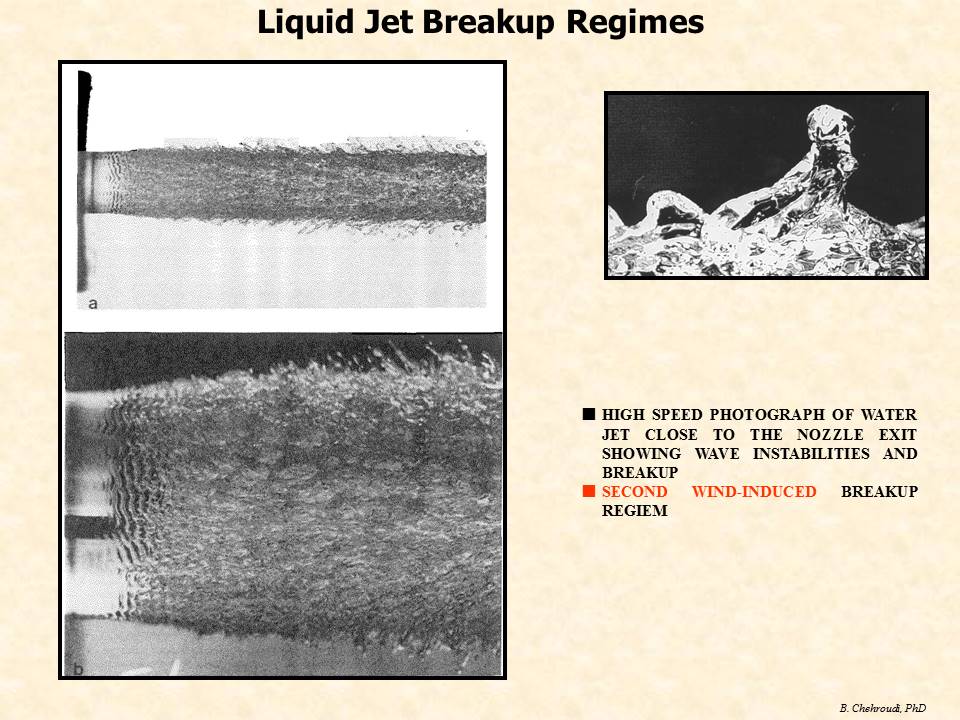

- Disintegration of the liquid jets

- Rayleigh criterion (no viscosity)

- Weber's criterion (effects of viscosity)

- Ohnesorge criterion for atomization (Ohnesorge Number)

- Liquid Breakup regimes

- Rayleigh regime

- First wind-induced breakup regime

- Second wind-induced breakup regime

- Atomization regime

- Influence of some parameters

- Jet velocity profile

- Nozzle length-to-diameter ratio

- Ambient pressure

- Disintegration of liquid sheets

- Drop breakup in air flow, turbulent flow, and viscous flow

- Types of Atomizers

- Pressure atomizers

- Air-assist atomizers

- Air-blast atomizers

- Effervescent atomizers

- Electrostatic atomizers

- Ultrasonic atomizers

- Diesel injector

- Gasoline-fueled injector

- Drop size distribution and measurements

- Graphical and mathematical representation of drop size distribution

- Averaged diameter and representative diameters

- Measurement techniques

- Patternation

- Drop size measurements and spray characterization

- Mechanical methods

- Drop collection on slides

- Molten-wax and frozen-drop approach

- Cascade impactors

- Electrical

- Charged-wire and hot-wire methods

- Optical methods

- Imaging-- photography and holography

- Single-particle light scattering (Phase Doppler Particle Analyzer, etc.)

- Diffraction size analyzer

- Drop evaporation

Day 2

- Gasoline port fuel injectors and injection system

- Multipoint port injection system

- Classes of gasoline port injectors

- Low pressure injectors

- Medium pressure injectors

- High pressure injector

- Air-assisted injectors

- Swirl injectors

- Heated vaporizing injectors

- Ultrasonic injectors

- Electrostatic injectors

- Key requirements of gasoline port injectors

- Deposit considerations

- Classes of gasoline port injectors

- Single-point throttle body injection system

- Feedback system

- Effects of injection parameters on engine performance and emission

- Injection timing and scheduling

- Spray targeting

- Spray momentum

- Mean drop size and size distribution

- Pulse-to-pulse variability

- Others

- Injection timing and scheduling

- Multipoint port injection system

- Flow of fuel and air in intake manifolds

- Details of Gasoline direct injection (GDI) and its effects on engine performance and emission of pollutants

- Comparison with Port Fuel Injection

- General operating strategy

- Injector requirements and spray characteristics

- Applications of different injector designs

- Fuel-air mixing processes

- Combustion control strategies

- Combustion chamber designs

- Injector deposits

- Unburned hydrocarbon and NOx emissions

- Future prospects

- Spray modeling and demonstration of computer software for spray calculation in engines

Day 3

- Diesel fuel spray, injector and injection system

- Fuel injection system

- Pumps

- In-line injection pump

- Distributor-type injection pump

- Single-barrel injection pumps

- Unit injector & unit pump

- Injector designs

- Nozzle holder

- Nozzles

- Others

- Pumps

- Overall spray structure

- Liquid fuel atomization

- Spray angle

- Intact core length

- Spray penetration

- Effects of several parameters on mean droplet diameter

- Spray evaporation

- Ignition delay

- Effects of fuel injection parameters on ignition delay period

- Mixing-controlled combustion

- Effects of fuel injection parameters on ignition delay and on engine performance, efficiency, and emissions

- HC emission mechanisms in diesel engines and its relation to fuel injection

- A brief on soot formation and fuel sprays

- Advanced topics (details of split injection, common-rail injection, interacting-sprays injection, ultra-high pressure fuel injection, and others effects on performance and emissions)

- Fuel injection system

- Summary and conclusion