Advanced Technology

Consultants |

home | help | email |

Welcome to

Advanced Technology Consultants

Laguna Niguel, California

USA 92677

Tel: 949 467 9233

(001 prefix outside USA)

Lugano, Ticino

Switzerland 6900

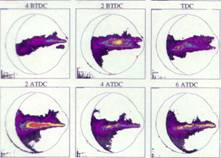

| Liquid Atomization, Sprays, and Fuel Injection Technologies |   Oscillating poppet injector producing a hollow-cone spray [left image) Interacting-sprays injection system shown at different crankangles (or time). Note that sprays impinging the far cylinder wall (picture is taken by sending a pulsed laser sheet and imaging from cylinder head using ICCD digital camera) [right image) |

|

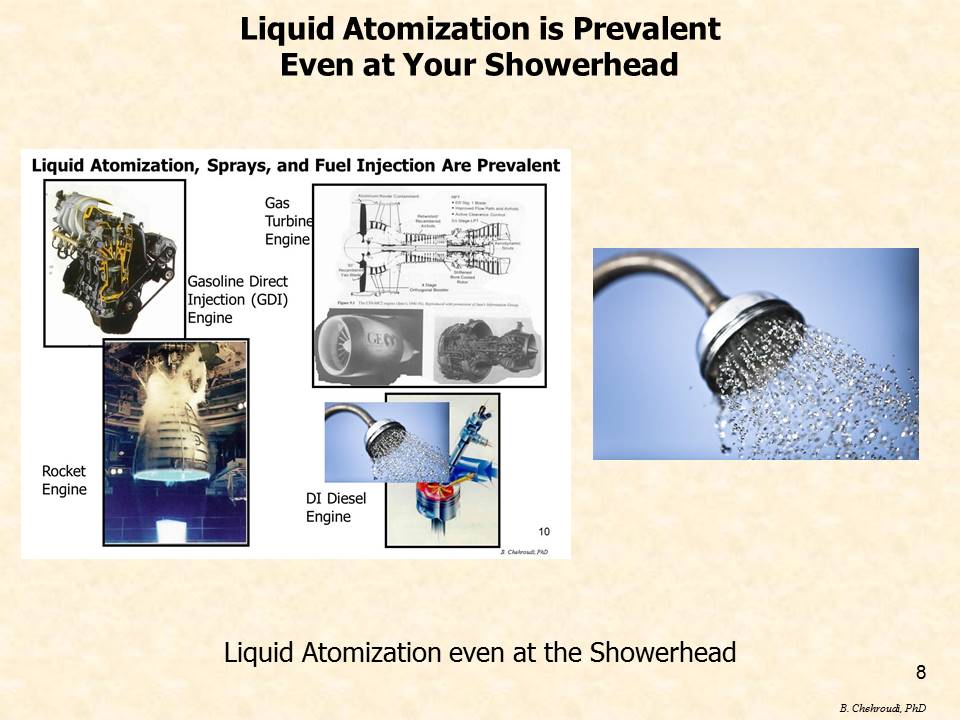

Atomization

of liquids is at the very heart of operations of many of the

devises we use on a daily basis. From our shower in the morning

(liquid water atomization process at t

This seminar is about understanding the processes of

liquid atomization and spray formation and relating this

understanding to fuel injection systems and emission of

pollutants in modern engines. Fuel injection is the key to

smooth, efficient, and low-emission operation of the

gasoline-fueled engines. In diesel and GDI engines, it is

shown that the story is also the same and even more critical. In

the aerospace industry, the engine thrust, efficiency, and the

emission levels are directly related to the performance of the

liquid fuel injector designs. In short, the liquid fuel

atomization and spray formation is in the heart of the majority

of stationary and mobile power generation machines. Other areas

such as electrostatic car-body spray painting, agricultural crop

spraying, ink jet printing, pharmaceutical nebulizers, spray

drying, and chemical liquid rockets, are just a few examples of

the very wide applications of the liquid spray production

The approach in this course is to build sufficient background through introduction of a consistent and widely-used terminology in sprays and atomization. Justifications, reasons, and purposes of the liquid atomization and spray formation are discussed along with presentation of different designs of atomizers and nozzles employed in various industries. Characterization methods of sprays are discussed after the definition and meaning of different averaged liquid droplet diameters are touched. Droplet size measurement devices are covered and examples are shown. Armed with these critical background information, the focus of the course is then heavily directed to the gasoline and diesel fuel injections, injector designs and their performance requirements for optimum engine operation with lowest possible emission of harmful pollutants.

Benefits of Attending:

Who Should Attend:

How to Arrange for a

Presentation: Due to ATC's low overhead, direct-contact clients are offered a competitive and cost-effective package. Individuals interested in these seminars should contact Advanced Technology Consultants (ATC) directly. Alternatively, this seminar (prepared by the ATC and delivered by a award-winning ATC consultant) are also sponsored by the Society of Automotive Engineers (www.SAE.org).

Electronic and hard

copies of the seminar materials can be purchased and are

only available through ATC. Contact ATC for price and

shipping.

NOTE: Professionally-prepared "audio-video Powerpoint-type presentations" of these seminars are available for purchase by the companies. Each slide is presented with a clear audio by the consultant, describing the subject, while a digital pointer guides the audience to where the attention is to be focused. Companies can put such audio-video presentations on their intranet to be used by their employees. It is a cost effective way of approaching professional training which also contributes towards R&D, design, and intelligent new product development. Presentations are updated every year at a fraction of the original cost. For a sample presentation click on the word "SPRAYS" in the picture to get a feel of how information is transferred (High-speed internet access is recommended. Otherwise, download may take a few more minutes). For more details and pricing please contact ATC.

Seminar Content

Day 2

∑ Gasoline port fuel injectors and injection system

∑ Spray modeling and demonstration of computer software for

spray calculation in engines Day 3

∑ Diesel fuel spray, injector and injection system

Testimonial

Instructor:

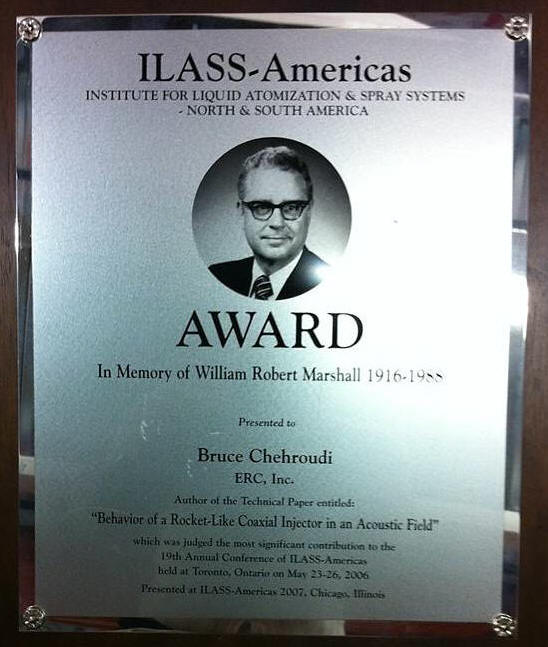

Bruce Chehroudi Dr. Chehroudi, has accumulated years of technical and leadership experiences in different capacities and organizations. This includes such positions as a Principal Scientist and Group Leader appointment at the Air Force Research Laboratory (AFRL) ERCInc, a Chief Scientist at Raytheon STX, a Visiting Technologist at Fordís Advanced Manufacturing Technology Development (AMTD) center, a tenured Professor of Mechanical Engineering at Kettering University and University of Illinois, and served as a Senior Research Staff/Research Fellowship at Princeton University. Dr. Chehroudi directed numerous multimillion dollar interdisciplinary projects in areas involving chemically reacting flows, combustion and emission of pollutants, sustainable and alternative energy sources, distributed ignition, material/fuel injection, advanced pollution reduction technologies, propulsion concepts, gas turbine and liquid rocket engines, combustion instability, laser optical diagnostics, spectroscopy, supercritical fluids and applications in environmental and propulsion systems, advanced composites, MEMS, nanotechnology, and micro fluidics. He has won many merit and leadership awards by such prestigious organizations as the Society of Automotive Engineers (1. Arch. T. Colwell Merit Award for technical excellence only to top 1% yearly, 2. Ralph R. Teetor Award for outstanding teaching/research/leadership, 3. Forest R. McFarland Award for sustained leadership in professional and educational service and a key contributor to the Continuing Professional Development Group, 4. Appreciation Award for 10 years of dedicated and inspiring service and commitment to providing quality technical education, and 5. Outstanding Faculty Advisor), American Institute of Aeronautics and Astronautics (Best Publication Award of the Year), Air Force Research Laboratories (1. Outstanding Technical Publication Award, and 2. STAR Team Award for demonstrating world-class combined scientific and leadership achievements), Institute of Liquid Atomization and Sprays Systems (Marshall Award for best publication with lasting contributions), Liquid Propulsion Sub-committee of Joint Army-Navy-NASA-Air Force (JANNAF) (Best Liquid Propulsion Paper Award involving undergraduate/graduate students), and the 2nd International Symposium on Turbulence and Shear Flow Phenomena (Top 10 Technical Publication Award). He has been a consultant with many organizations such as, Ford, GM, Honda R&D, AFRL, Honeywell, NASA, AFOSR, VW, Bosch, Siemens, NGK, Cummins, and TRW. Through professional societies, Dr. Chehroudi delivers invited professional seminars on Management of R&D Teams and Organizations, Management of Innovation, Combustion and Emission of Pollutants in Automotive and Gas Turbine Engines, Ignition Issues, Gasoline Direct Injection engines, R&D on Homogeneously-Charged Compression Ignition (HCCI) engines, and Liquid Injection Technologies. He has a PhD in Mechanical & Aerospace Engineering and Post-Doctoral Fellow (Princeton University), MS in Mechanical Engineering (Southern Methodist University, Summa Cum Laude), MS in Economics (Swiss Finance Institute, Magna Cum Laude), a senior member of American Institute of Aeronautics and Astronautics Propellant & Combustion Committee (2008-present), and is an Associate Fellow of American Institute of Aeronautics and Astronautics. Dr. Chehroudi acts as a reviewer for many scientific and engineering journals and publishers, has delivered over 200 presentations in technical meetings and to nontechnical audiences, over 20 technical reports (Princeton University, General Motors, Ford Motor Co, Department of Energy, NASA, Air Force Research Laboratory), five 600-plus-page monographs on combustion and emission of pollutants from mobile power plants, ignition technologies, liquid material injection, and nanotechnology, two book chapters on propulsion system combustion instability and applications of graphene (a nanotech product) in ignition and combustion of fuels, ground-breaking patents on applications and synergy between nanotechnology, light, and chemical reaction for a light-activated distributed ignition of fuel-air mixtures, and has more than 150 publications with extensive experience in both scientific and management areas and intensive trainings in finance and financial engineering

NOTE: Contact Advanced Technology Consultants for consulting needs and opportunities in this area. Copyright 2015 - Advanced Technology Consultants- All Rights Reserved |

|